Drying Co-operative Sensebezirk, Tafers, Switzerland

Updating of drying system

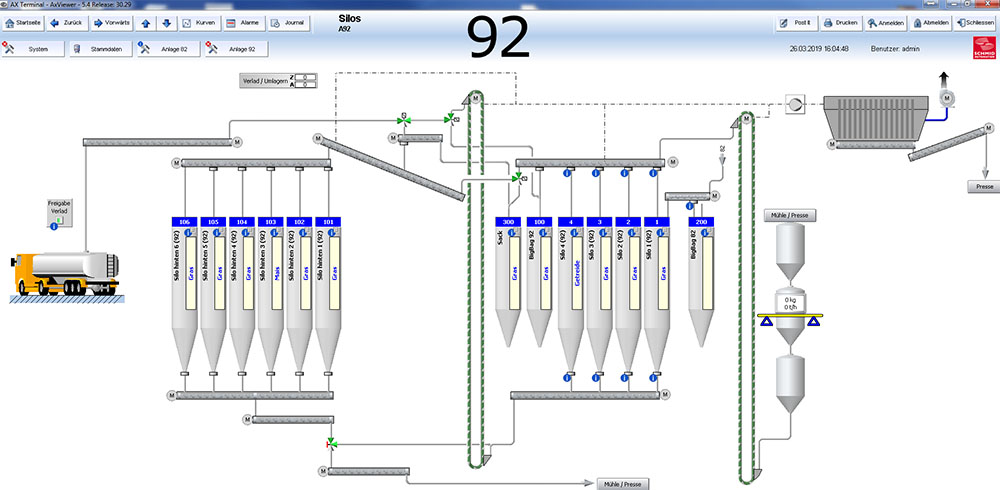

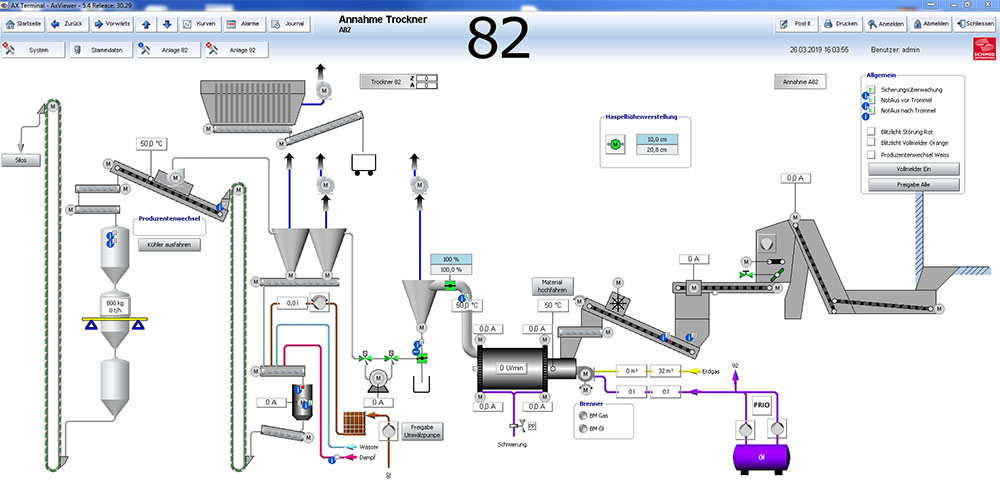

The plant consists of two drying lines. They date back to the years 1982 and 1992 and used to be operated through mimic diagrams before the update. We modernised the complete control system. All the control cabinets including the low-voltage main distribution board were replaced. For this purpose, an entirely new process control system was implemented and put into service.

Client

Drying Co-operative Sensebezirk, Tafers, Switzerland

Plant type

Drying system

Project execution

2018 to 2019

Project scope

- 750 data points

- Server cabinet

- 2 MCCs, total 10 panels

- Low-voltage main distribution system, total of 2 panels

- 2 control boxes

- Conversion of an MCC

Our services

- Concept design and consulting

- Stock-taking on site

- Creation of flow chart

- Creation of equipment list

- Overall electrical engineering

- Software performance description

- Software programming

- Interface with weighing scales

- Engineering of visualisation system

- Switchgear and control system

- On-site conversions

- Signal test and start-up

- Operator training

Technology applied

- automationX

- PROFINET

- EPlan P8

Contact

Marcel Fust, Senior Process Automation Consultant, Schmid Automation AG