IO-Link field cabling

We successfully commissioned a process control system with IO-Link sensors/actuators. As part of the peripheral system, IO-Link masters were mounted directly in the field and integrated into the Profinet infrastructure. IO-Link technology makes it possible to integrate the field level into automation and supports the requirements of digitalization and Industry 4.0 through this networking. Based on our experience, we see the following decisive advantages:

Mounting/Cabling

- Use of standard 3‑core unshielded cable for all types of sensors/actuators

- Connection cable can be used ready assembled

- Short connection cables from sensor/actuator to the master

Service/Maintenance

- Extensive diagnostics through bidirectional communication

- Fast access to sensor/actuator parameter data

- Sensor exchange via Plug & Play for an identical one

The additional design effort is justified by the advantages of ready-made M12 cable connections. However, precise design of the locations of all masters in the field is necessary in order to determine the appropriate cable lengths. Coordinating with the installation company in advance makes the design much easier.

By using IO-Link, the customer obtains increased system availability during operation, due to transparency down to the sensor/actuator level. IO-Link devices can provide information about the device status and thus lead to enormous added value in terms of system stability and reliability.

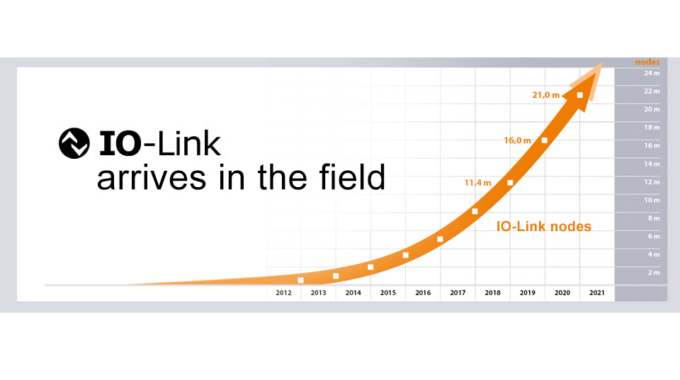

The rapid development of IO-Link technology is also reflected in the constantly increasing use of these components, as the above graphic shows: