Kunz Kunath AG, Weinfelden, Switzerland

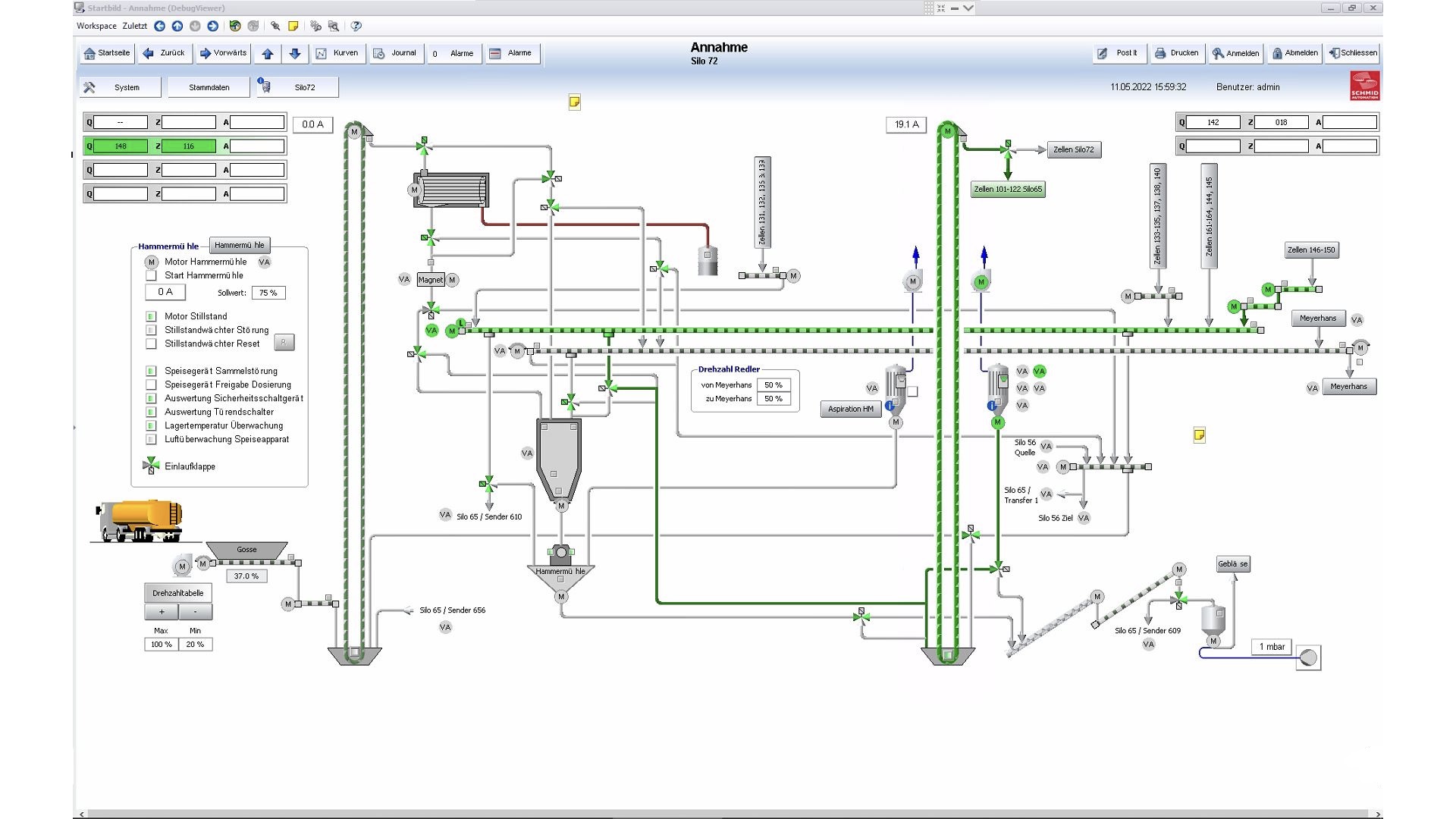

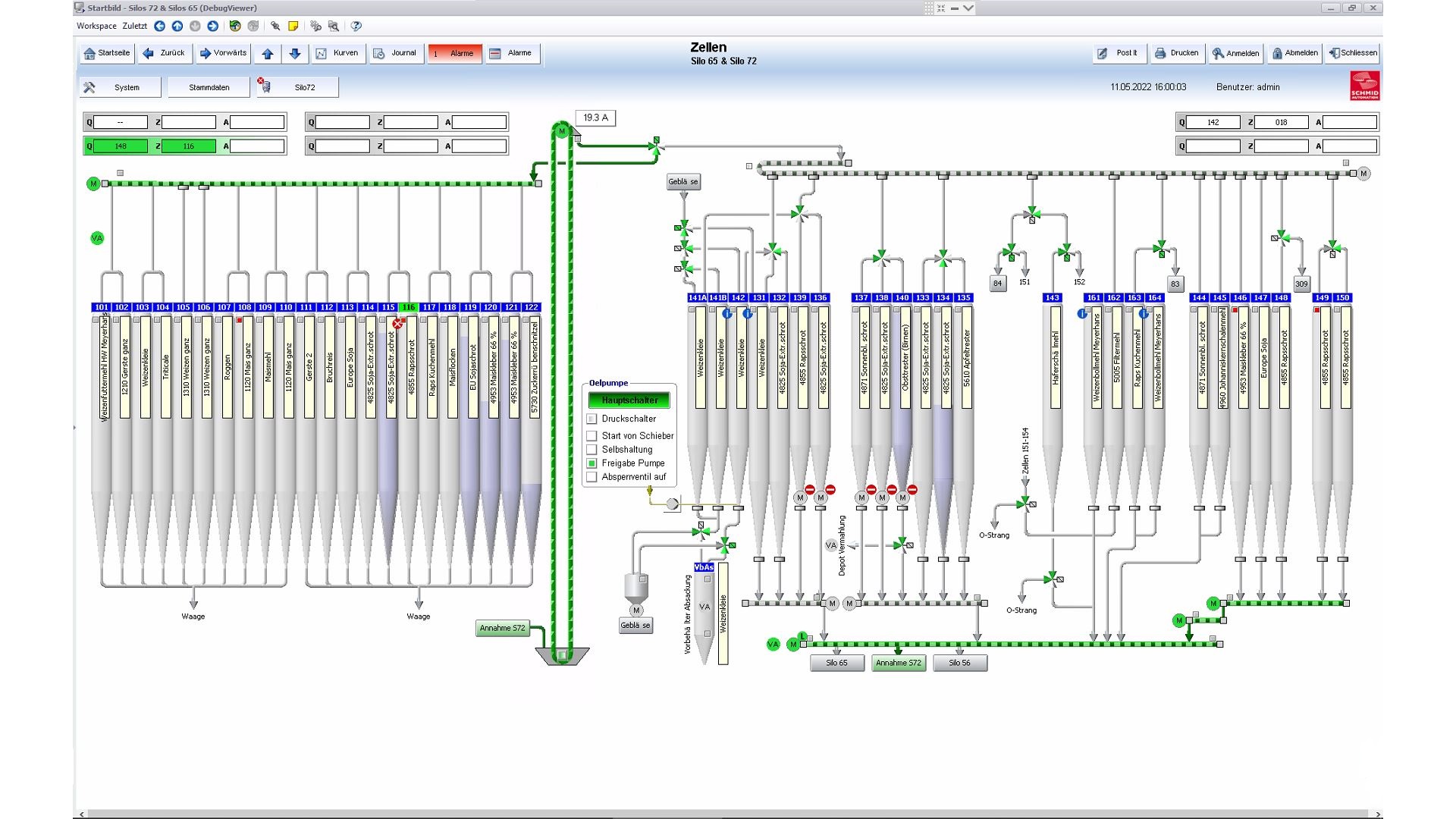

Modernisation silo 72

The existing control system and mechanics from 1970 was converted during running operation. For such a refurbishment operation at the “open heart”, an overall project management was paramount. As part of the project management, we coordinated the project participants such as production, process automation, electrical installation and plant engineering. Staging workshops were organised and carried out, schedules were drawn up and continuously updated, and meeting minutes were taken. In addition, we were responsible for the realisation of the process automation and electrical installation scope. We invited tenders for the electrical installation on behalf of the client and submitted a tender proposal to the client, who awarded the work to a local contractor. We supervised the installation as the client’s representative.

Client

Kunz Kunath AG

Plant type

Feed mill

Project execution

2020 to 2021

Project scope

- 680 data points

- 2 MCC, total 6 fields

- 5 local cabinets

- 1 Operating station

- 1 Server as emergency service station

Our services

- Concept design and consulting

- Overall project management

- Stock-taking on site

- Electrical engineering

- Installation planning incl. tendering

- Creation of software performance description

- Programming of software

- Project engineering of visualisation system

- Switchgear construction

- Site supervision electrician

- On-site conversions

- Signal test and start-up

- Operator training

Technology applied

- automationX

- PROFINET

- EPlan P8

Contact

Marcel Fust, Senior Process Automation Consultant, Schmid Automation AG