ARA Lauterbrunnen, Switzerland

Sewage treatment plant

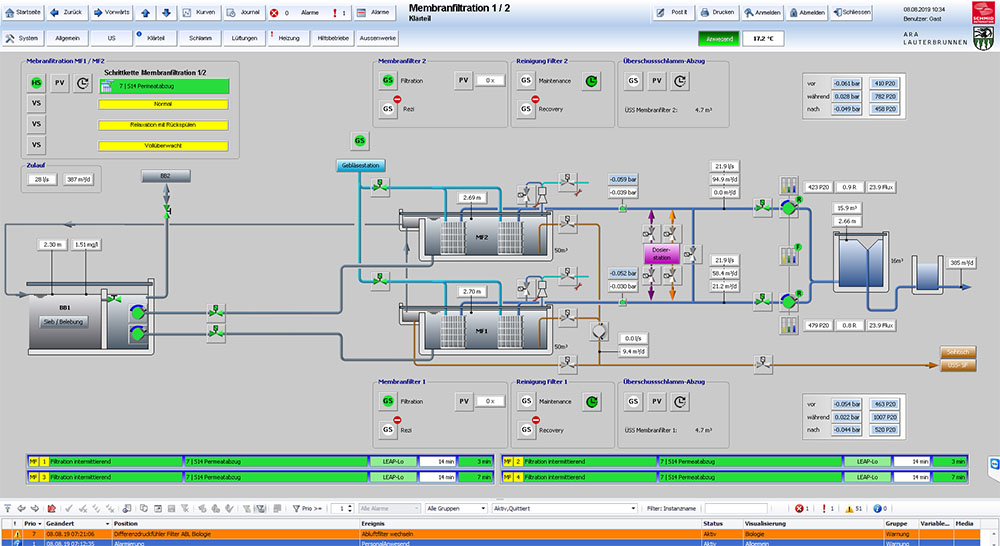

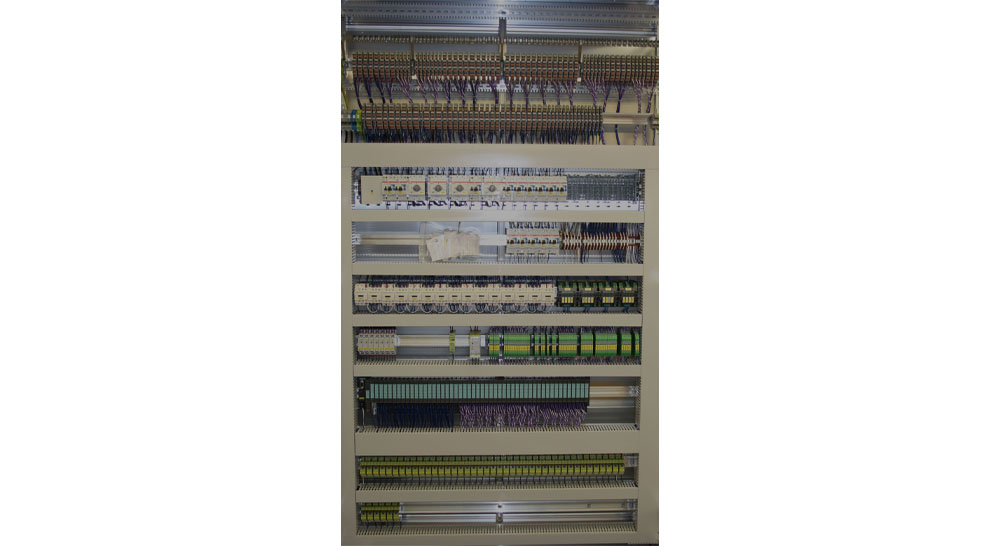

The plant was upgraded both biologically and mechanically. The focus was on the replacement of the biology by a state-of-the-art membrane biology technology. For this purpose, various mechanical sub-systems were rehabilitated and replaced. We were entrusted with the supply of the new switchgear for the new biology and with implementing the process within the process control system. For this purpose, a number of processes were optimized and upgraded. In addition, the process control system dating back to the year 2009 was updated to the latest version and an SMS-alerting system with stand-by planning was integrated. Also the five outstations were integrated in the process control system via telecontrol.

Client

ARA Lauterbrunnen, Switzerland

Plant type

Sewage treatment plant

Project execution

2017 to 2019

Project scope

- 2,400 data points

- 2 MCCs, total 7 panels

- Low-voltage distribution system, total 2 panels

- 3 local cabinets

- 2 outstation cabins (new)

- 3 outstation cabins (rebuilds)

Our services

- Concept design and consulting

- Switchgear planning

- Programming of software

- Project engineering of visualisation system

- Signal test and start-up

- Operator training

Technology applied

- automationX

- EPlan P8

Contact

Marcel Fust, Senior Process Automation Consultant, Schmid Automation AG