Karl Bindewald GmbH, Bischheim, Germany

Data analysis

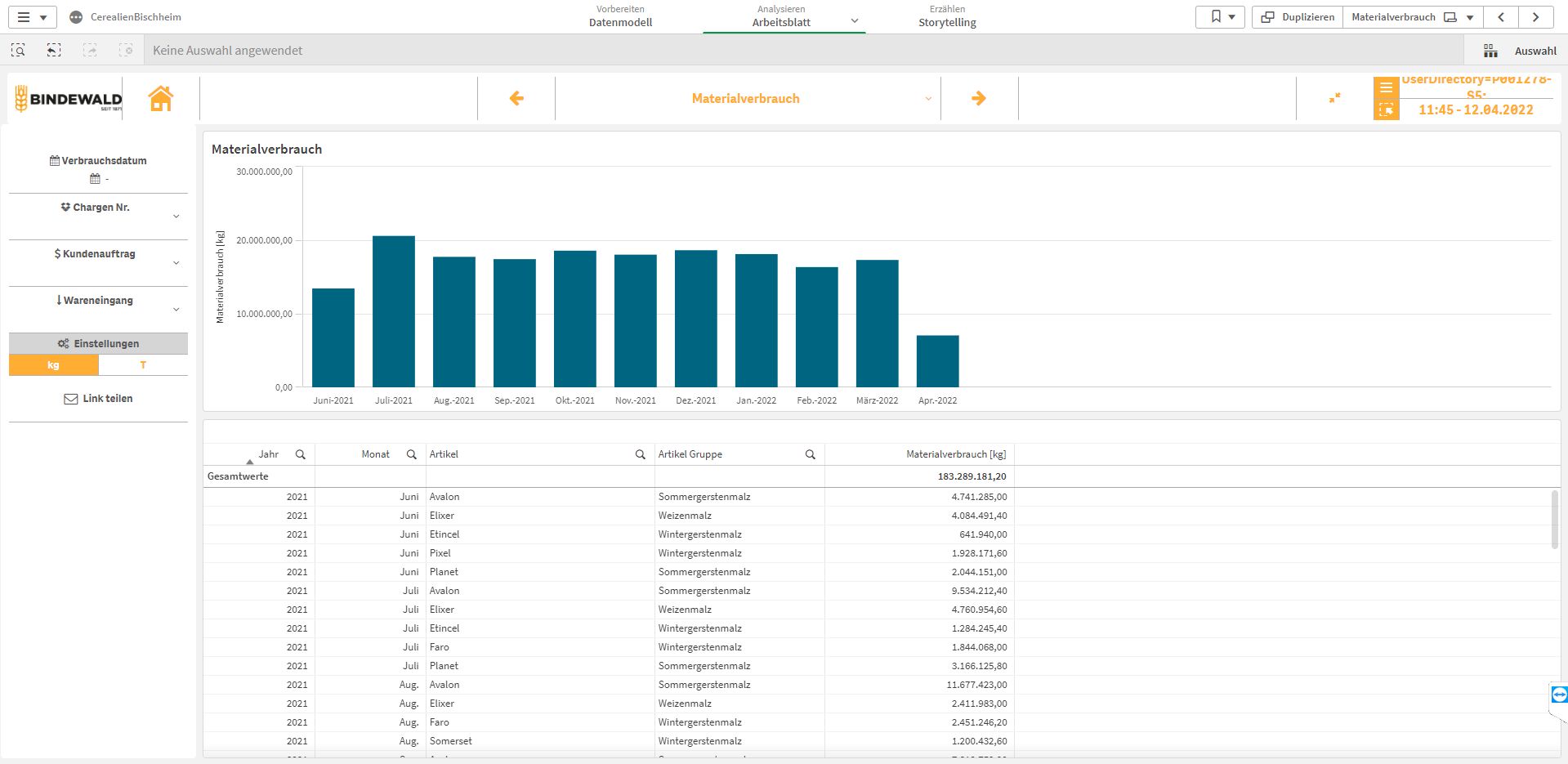

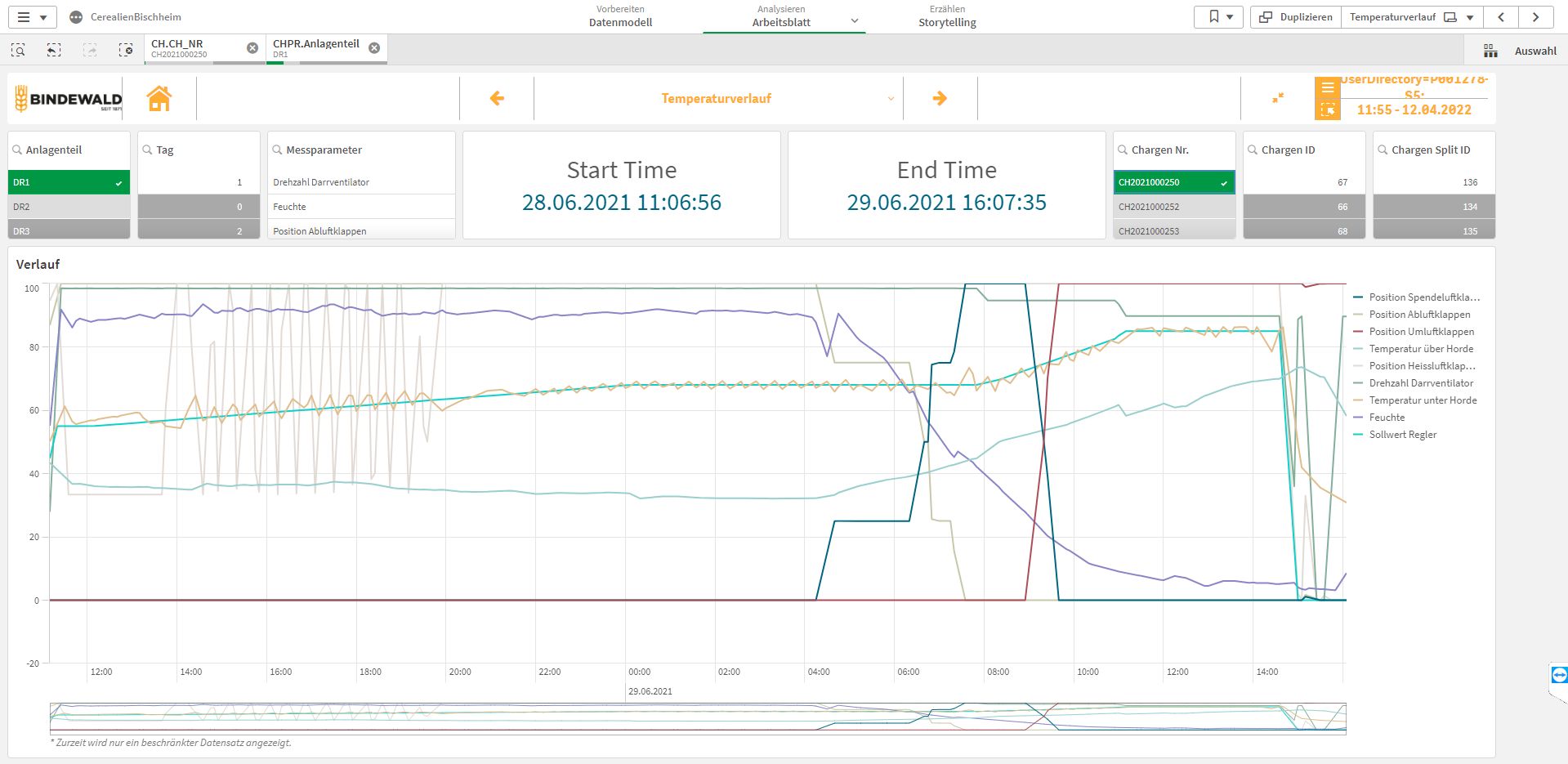

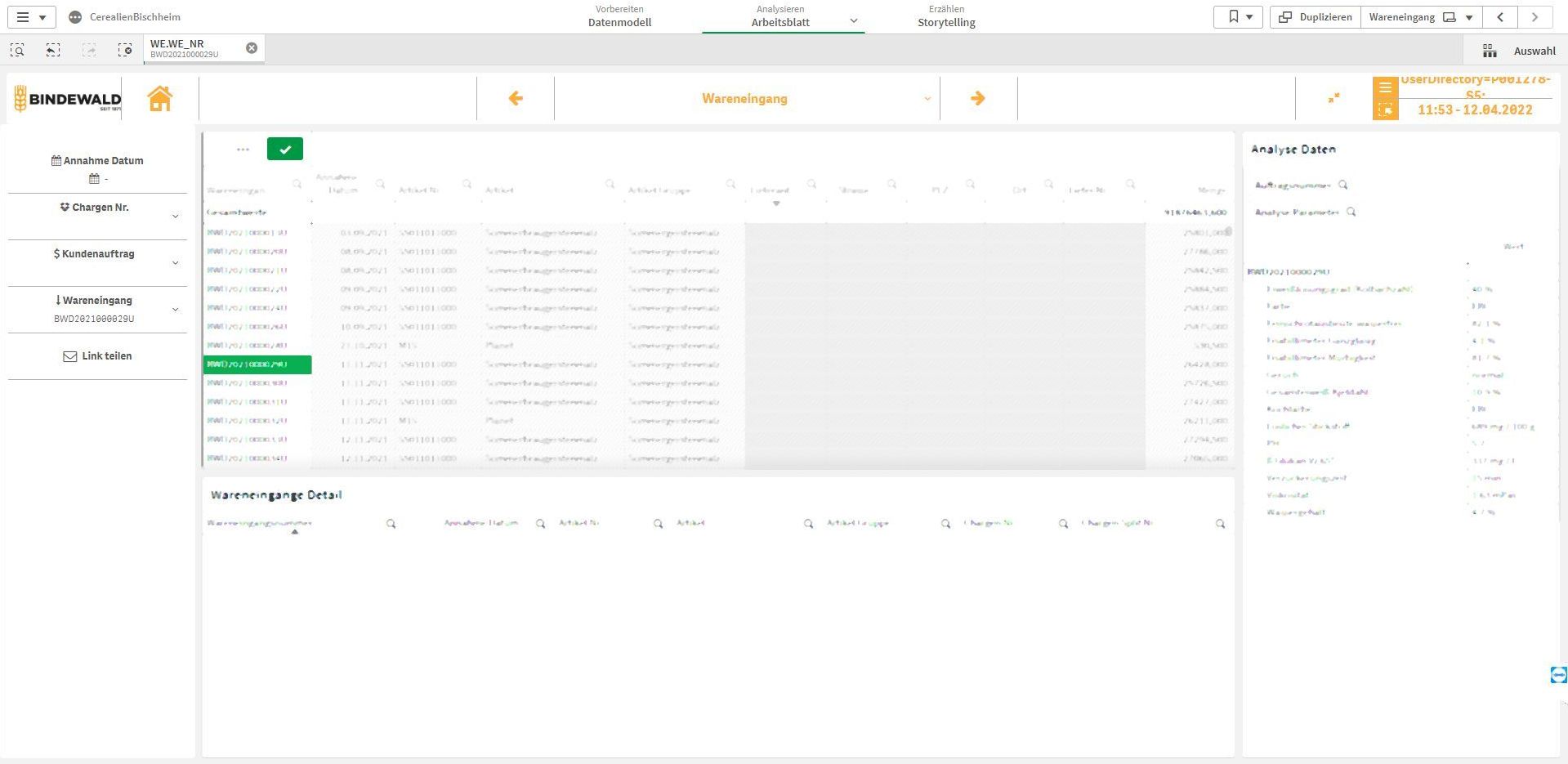

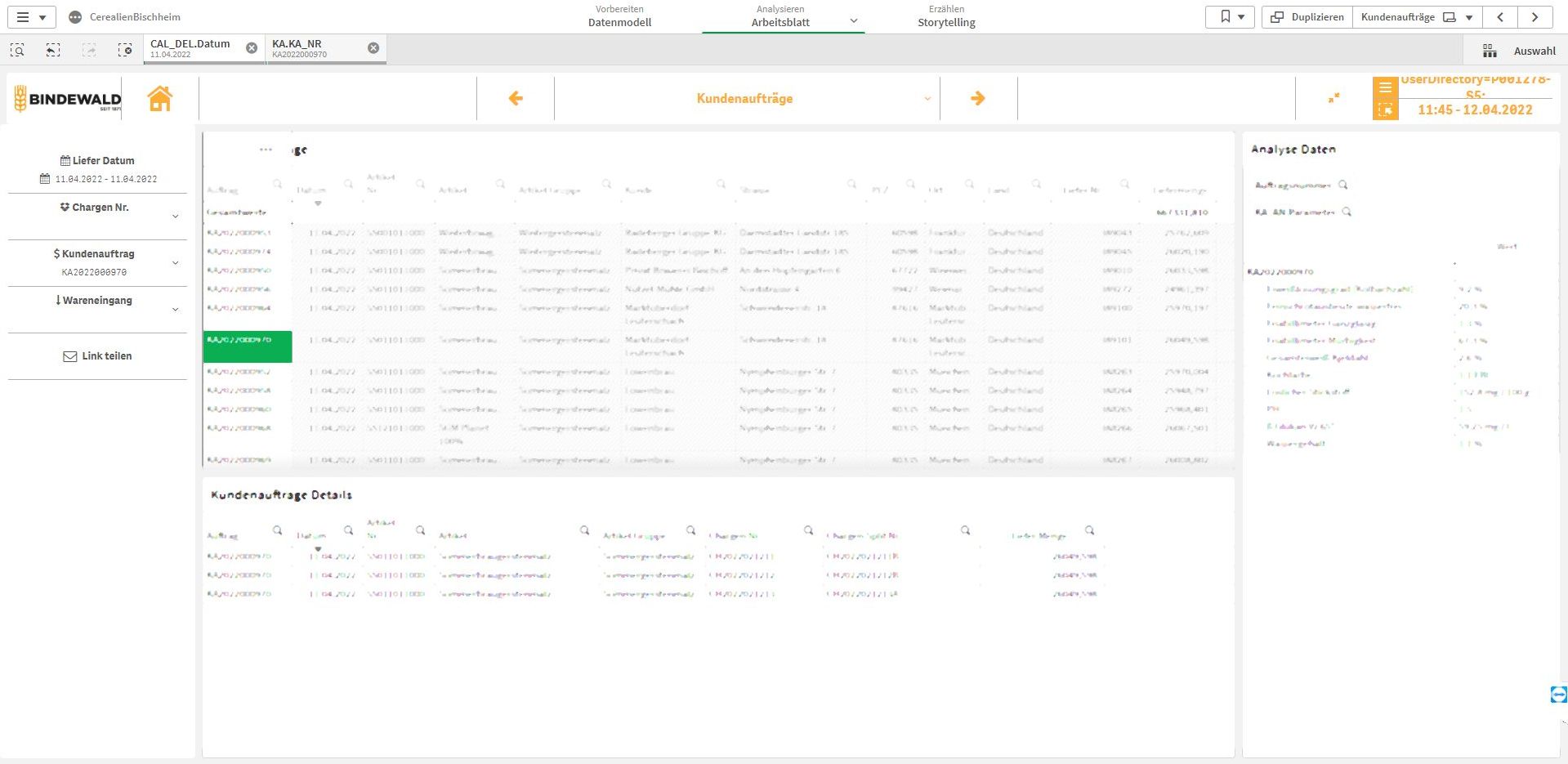

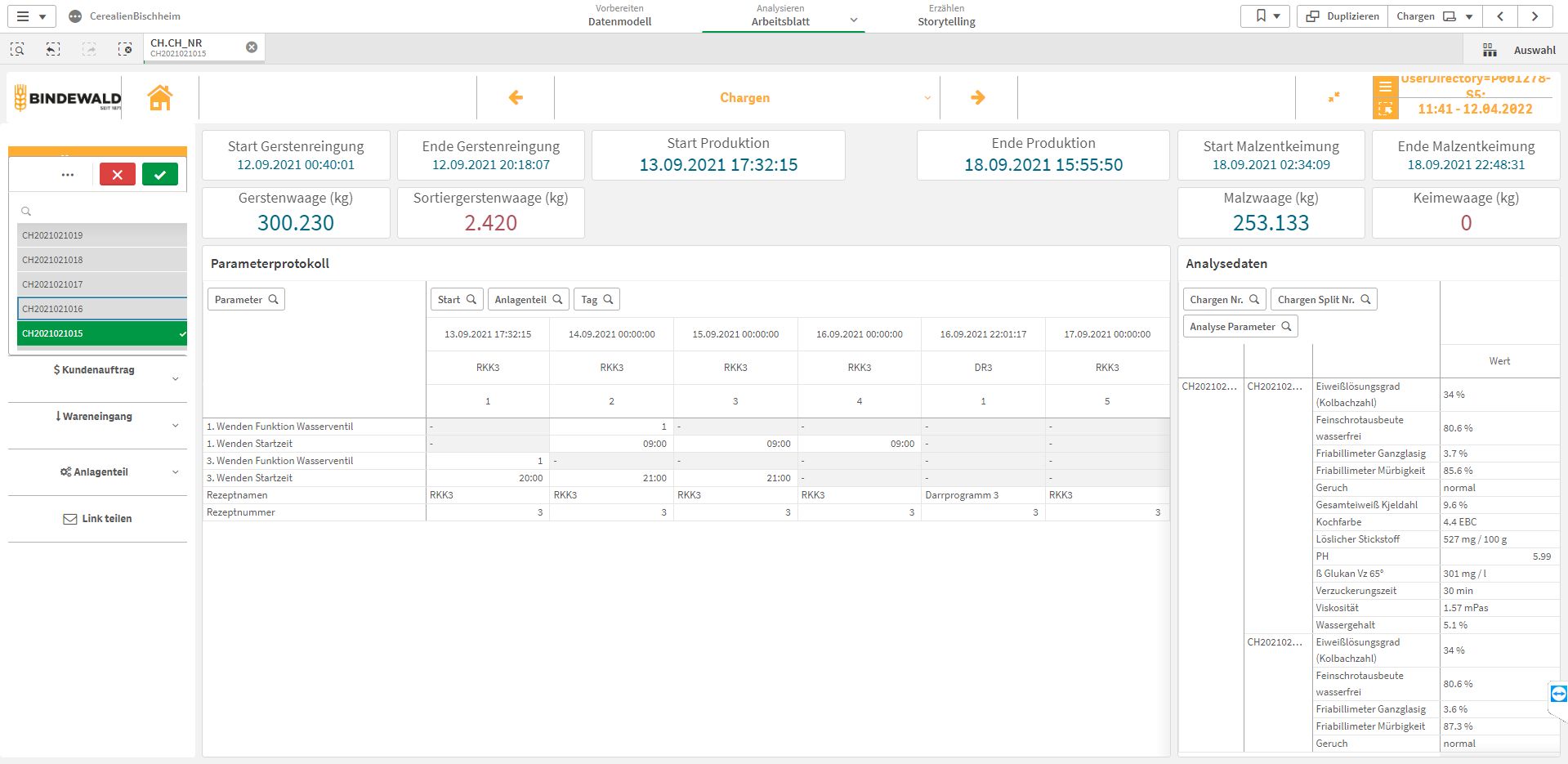

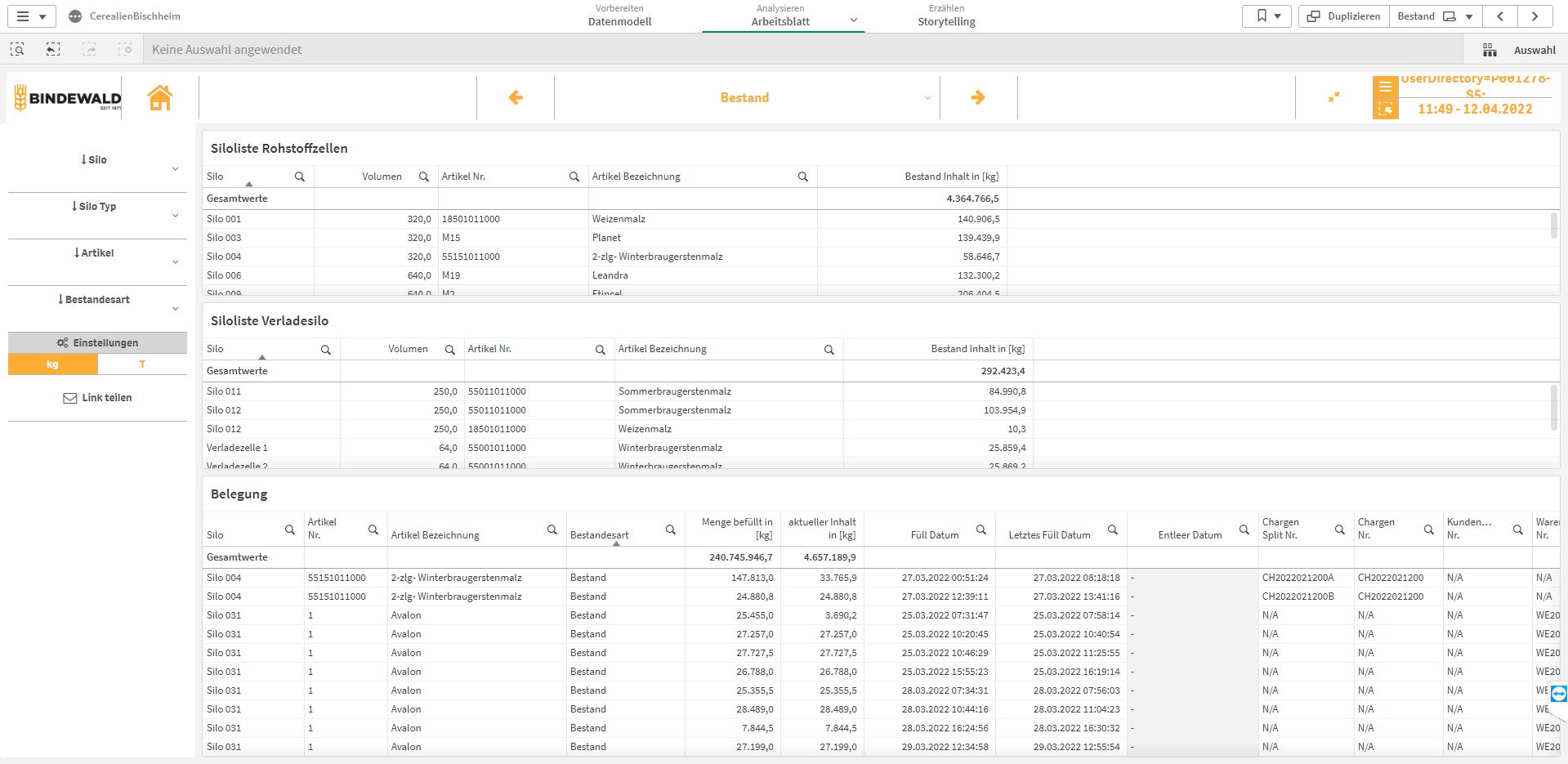

The customer’s requirement was to bring together all silo control, malting and laboratory data on a uniform platform. It should be possible to flexibly expand the system with additional data sets. In order to solve these challenges, data is collected by the control system automationX and transferred to the BI tool Qlik Sense via SQL databases. In Qlik Sense, the data is consumed and analysed by with reports and dashboards. The reports can also be edited and further developed by the customer.

With this solution, the customer receives continuous batch tracking with convenient forward and backward functionality. Temperature curves of the kiln or the individual laboratory reports can also be viewed for each batch. This means that the customer is optimally equipped for the future and meets all the requirements of the various stakeholders such as quality management, customer audits, etc. in the best possible way by having access to all production and quality data via web browser at any time.

Client

Karl Bindewald GmbH

Plant type

Malthouse

Project execution

2021 until 2022

Project scope

- 3200 data points malthouse

- 2000 data points bulk storage

- 1 Server Qlik application

- 7 Preconfigured reports and dashboards

Our services

- Concept design and consulting

- SQL-Datenbank Engineering

- Create Qlik data model

- Create Qlik reports and dashboards

- Start-up

- Operator training

Technology applied

- Windows Server 2019

- Microsoft SQL Server

- Qlik Sense

Contact

Karl Zoller, Senior Process Automation Consultant, Schmid Automation AG